使用 E+E 传感器进行 温室 的优势

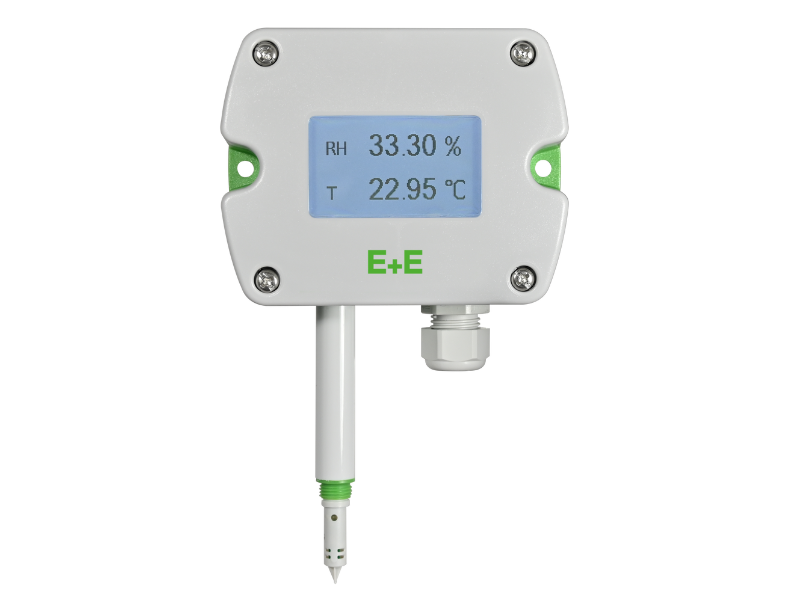

Modern greenhouses expose sensors to demanding conditions such as high humidity, dust, biofilm, and chemicals. Measurement devices must deliver stable and reliable readings even at relative humidity above 95 %, during active humidification, heavy contamination, and H₂O₂ sterilisation. Without stability, drift, sensor failure, and crop losses may occur. E+E Elektronik sensors are specifically designed to operate in these demanding conditions. Smart and robust designs ensure maximum reliability and long-term stability:

- Heated humidity sensors: The integrated sensor heating (High Humidity Guard) prevents condensation from forming on the sensor and ensures constant measuring accuracy, even in high humidity. This extends the service life and reduces maintenance requirements.

- IP65/IP67 housing with interchangeable filter: Protects against dust and water ingress and ensures high operational reliability even during high-pressure cleaning or H₂O₂ sterilisation.

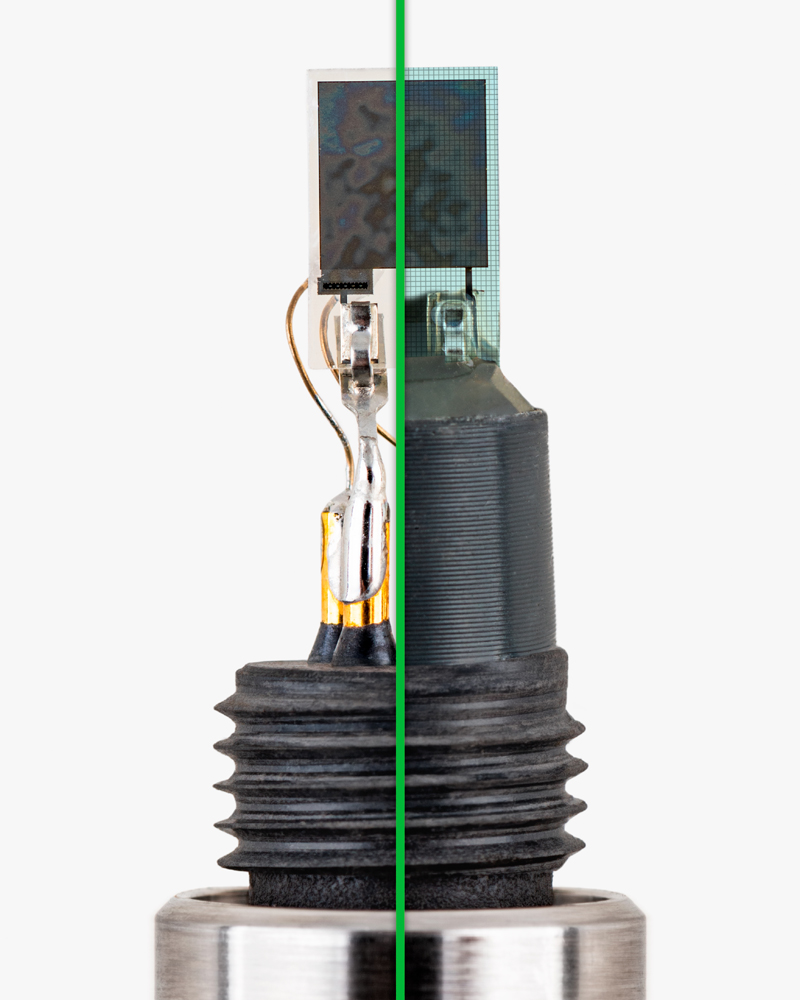

- E+E sensor coating: A specially developed hygroscopic protective layer shields the active sensor area. It protects against dust, corrosion, and long-term moisture exposure. This ensures stable measurement performance.

- Innovative sensor encapsulation: A dedicated protective capsule shields the electronics from fine dust, dirt particles, and aggressive chemicals. This ensures reliable operation even in harsh and contaminated environments.

Climate control is a key cost factor in greenhouse operation. Even small measurement inaccuracies can lead to incorrect VPD (Vapor Pressure Deficit) calculations, which is the difference between the maximum possible and actual air humidity. Incorrect VPD calculations result in inefficient ventilation, unnecessary heating, and excessive humidification. The VPD is a critical control variable for plant transpiration. If the VPD is too low or too high, plants react by reducing their nutrient uptake which is an inefficient energy use.

E+E sensors offer outstanding measurement accuracy:

- Temperature: ±0.1 °C

- Humidity: ±1.3 % RH

- CO₂: ±50 ppm

These accuracies lead to actual savings. For example: In a 5-hectare greenhouse with an average daily energy consumption of 60,000 kWh, an imprecise VPD calculation of just ±0.2 kPa can lead to up to 30 % higher energy consumption. This corresponds to 18,000 kWh – or approx. $1,800 in additional daily costs (at an electricity price of $0.10/kWh). Using high-precision sensors helps to avoid these losses by increasing yield, create more cost-effective stable growing conditions, and significantly reducing operating costs.

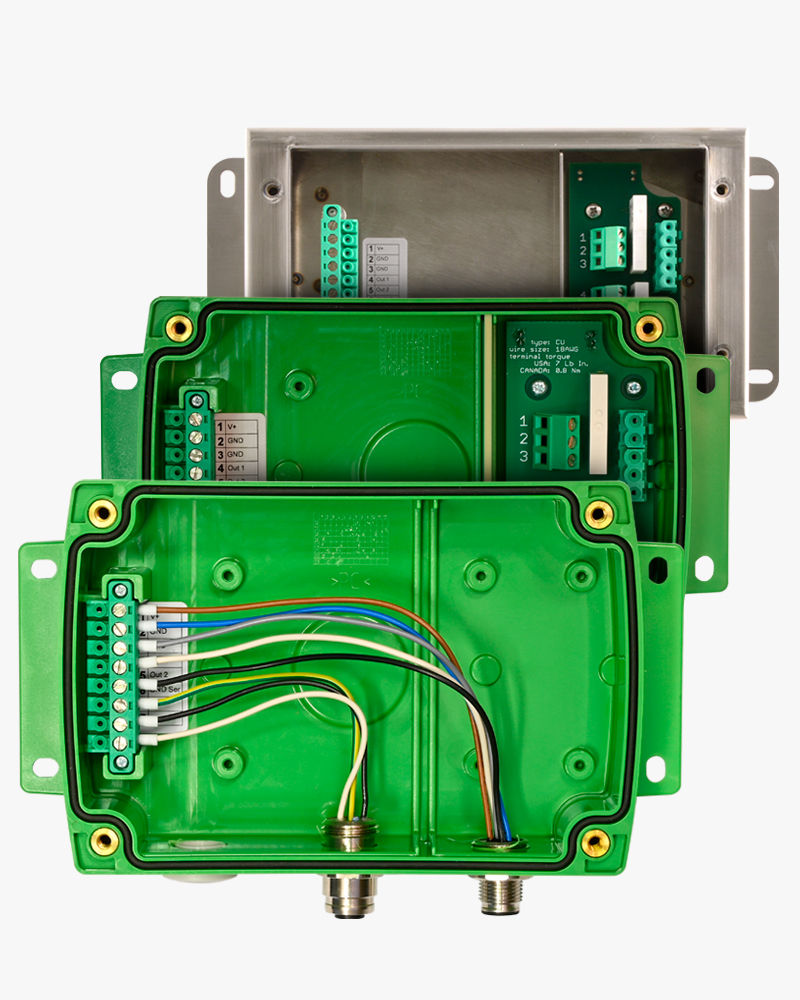

E+E sensors support common communication protocols such as Modbus RTU, as well as analog and digital output signals, including 4–20 mA and 0–10 V. In addition, the output signals can be individually configured, enabling seamless integration into existing control architectures. Thanks to this flexibility, the sensor solutions are ideally suited for retrofit projects in traditional greenhouse control systems and modern IoT- or cloud-based climate management platforms. Integration requires no additional programming and saves valuable time during commissioning.

In large-scale or hard-to-reach installations, sensor replacement must be quick, straightforward and tool-free. E+E Elektronik offers sensors with a modular design. These allow sensor modules to be replaced within seconds without disassembling the entire device or performing time-consuming recalibration. This maintenance-friendly construction minimises downtime and significantly reduces operating costs.

适用于 温室 应用的传感器解决方案

关于 温室 的问题?

探索 E+E 的传感技术和先进的传感器校准技术。

我们的全球团队将帮助您找到适合您生产的解决方案。