使用 E+E 传感器进行 烟草 的优势

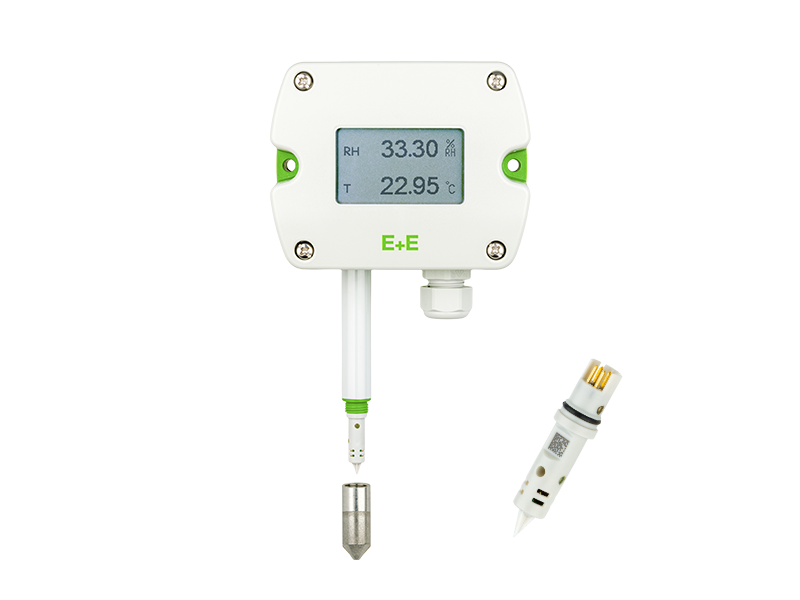

干燥烟草太快会损坏叶子的细胞结构。湿气分布不均可能导致储存问题和味道变化。E+E传感器非常准确地测量温度和相对湿度。它们快速的响应时间和长期的稳定性使得可以持续实时控制过程空气,无论是在烟熏干燥还是在流化床干燥中。精确的控制可以防止过干或过湿,同时减少能量消耗,因为加热和通风系统可以根据需要精确运行。在封闭循环空气系统中,最多可以回收80%的空气,高精度传感器在最小化能量输入和准确管理过程空气的湿气负荷中起着关键作用。

烟草的干燥是一个困难的过程。它涉及高温、强气流和细小的灰尘。当干燥使用环境空气时,还会使用磷化氢来对抗害虫。磷化氢非常活泼,可能会侵蚀铝和铜等金属。此外,细小的烟草灰尘可能导致测量误差。E+E传感器专为这些困难条件而设计。它们智能且坚固,确保高可靠性:

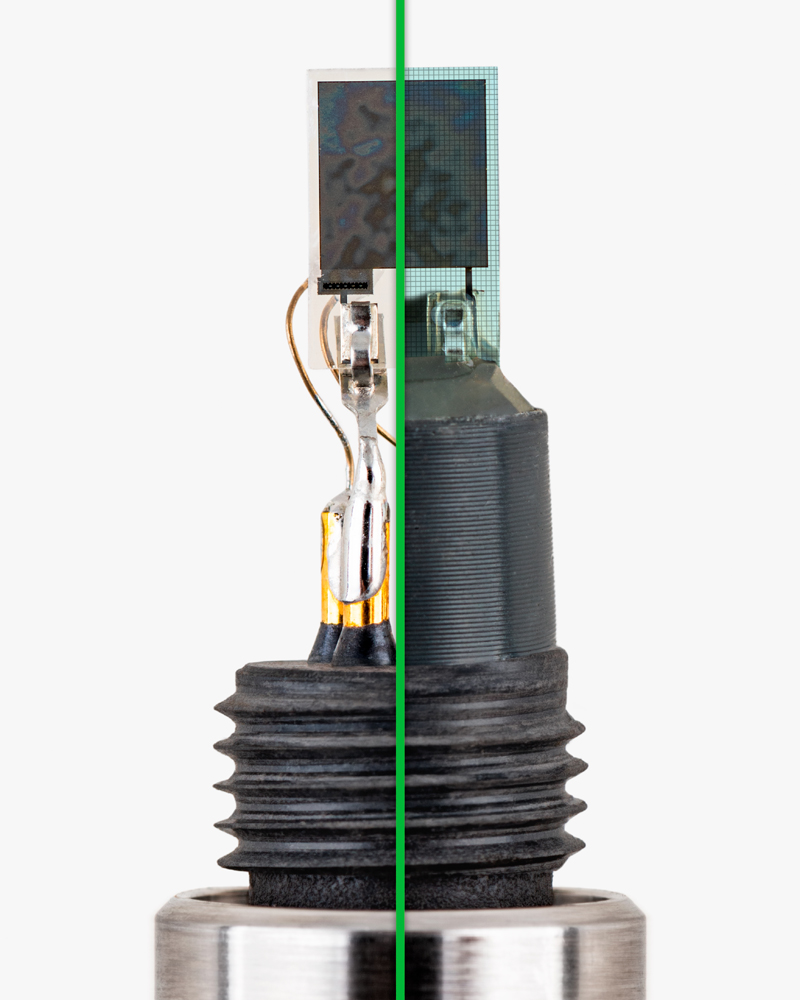

- 加热湿度传感器:集成的传感器加热器(高湿度保护)防止水分在传感器上形成。因此,即使在高湿度或水分产生的情况下,测量精度也保持不变。这延长了传感器的使用寿命,并减少了维护工作量。

- IP65/IP67外壳与可更换过滤器:外壳防尘防水。因此,即使在高压清洗或H₂O₂灭菌等困难条件下,可靠性也很高。

- E+E传感器涂层:一种特殊的吸湿保护层覆盖了活跃的传感器表面。它保护传感器免受灰尘、腐蚀和湿气的影响。这确保了稳定和准确的测量值。

- 创新的传感器包装:一种特殊的保护胶囊保护电子元件免受细小灰尘、污垢和化学污染物的影响。因此,传感器在严重污染的环境中也能可靠工作。

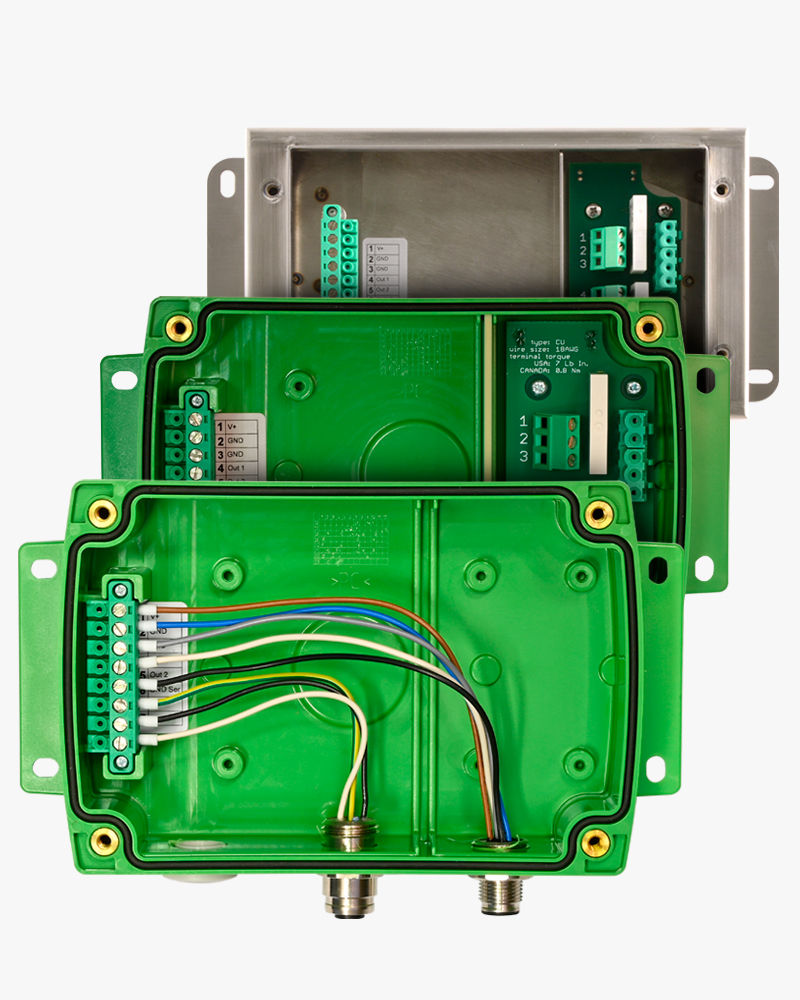

工业烟草干燥过程高度自动化。无论是传统干燥系统还是现代流化床干燥机,都配备有中央控制单元,用于管理温度、湿度、气流和能源供应。为避免在改造或维护期间出现停机,快速且简便的传感器集成至关重要。

E+E 传感器可通过标准化接口(如 Modbus RTU)、模拟和数字输出,无缝集成到现有系统中。输出信号可单独预配置,从而最大限度地减少安装工作量。

这使得传感器既适用于新建系统,也适用于改造项目,并可与现有自动化基础设施实现最大兼容性。

干燥室和烟草加工中的输送线通常难以接近。任何停机时间都会直接影响产量和产品质量。因此,传感器解决方案不仅必须提供可靠的测量,还需要最小的维护。E+E Elektronik提供了一种智能解决方案:传感器的模块化设计允许在不拆卸整个设备或进行耗时的重新校准的情况下,快速现场更换传感器模块。这在磷化氢暴露或严重灰尘积聚的区域尤其是一个重大优势。可更换性显著减少了维护工作,最小化了停机时间,并确保长期的操作可靠性,这在高产能生产线中是一个可衡量的好处。

适用于 烟草 应用的传感器解决方案

在烟草烘干行业,温湿度传感器在控制系统中发挥着重要作用,为系统的精准控制提供基础,从而帮助提高工作效率,节约能耗。E+E温湿度传感器被应用于客户的烘干设备,具有稳定的性能、高精度和优质的服务,用户非常愿意选择我们的产品。

关于 烟草 的问题?

探索 E+E 的传感技术和先进的传感器校准技术。

我们的全球团队将帮助您找到适合您生产的解决方案。