Saving time and cost with humidity measurement

Condensation Guard and rapidX in the HTS401

In many applications, relative humidity (RH) is not monitored for comfort but as a critical process variable. Whether in a data centre, cleanroom, cold store, livestock housing or climate control or food maturation, humidity and temperature must be monitored continuously. This is exactly where the HTS401 excels. It combines highly accurate humidity and temperature measurement with two unique features that make a noticeable difference: Condensation Guard and rapidX technologies.

This article details how both features save money, time, and hassle in day-to-day use.

Why condensation and calibration are critical

Humidity sensors are often exposed to harsh or unstable environmental conditions.

Typical challenges include:

- Relative humidity repeatedly rising to just below 100 % RH

- Exposure to sudden temperature drops caused by ventilation or cold-air supply

- Temperature drops can result in condensation forming on filter caps and sensing elements

- Chemicals added to the atmosphere that lead to contamination of the sensing element

When water reaches the sensor as condensation, two main problems arise:

- Delayed response time- the sensor indicates saturation even when the ambient air becomes drier. The readings stay close to 100 % RH.

- Accelerated corrosion, contamination, and long-term drift.

In addition, humidity and temperature sensors in validated or quality-critical processes must be calibrated regularly. Traditionally, this means removal, shipping to a lab, return shipment, and recommissioning. It can also mean time-consuming on-site calibration of the measuring devices. Depending on the process, a critical measurement point may not be available for several weeks.

The HTS401 alleviates both challenges.

The Condensation Guard in the HTS401 protects against the effects of condensation

The HTS401 is designed for use in demanding environments. In addition to the E+E sensor coating, the sensor features special heating functions with its Automatic Recovery (ARC) and the Condensation Guard. While ARC is primarily aimed at chemical exposure, the Condensation Guard (CG) was developed specifically for high-humidity operating conditions.

How the Condensation Guard works:

- The HTS401 continuously monitors the humidity conditions at the sensing element.

- If a defined threshold is reached – typically between 95 and 99 % RH – this indicates impending condensation on the sensor.

- At that moment, the Condensation Guard increases the temperature of the sensing element slightly.

- This reduces the relative humidity directly at the sensor - water on the element evaporates faster and condensation is either prevented or cleared quickly.

As a result, the output signal remains stable even if the environment repeatedly approaches the saturation limit. This reduces measurement errors and drastically reduces downtime in areas such as cold rooms, agricultural ventilation systems, and outdoor installations.

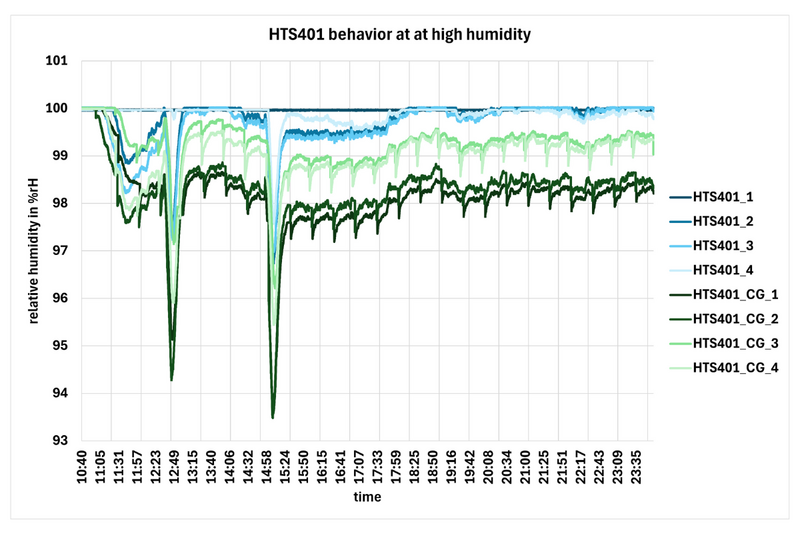

Tests with the HTS401 clearly demonstrate what this looks like in practice.

Climate chamber test at 15 °C and close to 100 % RH

To prove its reliability, several HTS401 units were operated in a climate chamber at 15 °C. The humidity control was set to 95 % RH and fluctuated between 95 and 100 % RH. Condensation formed on the test samples.

Two groups were run in parallel:

- HTS401 with Condensation Guard disabled

- HTS401 with Condensation Guard enabled

The measurement data show:

- The sensors without Condensation Guard spent a large part of the measuring time in the saturation range. Depending on the channel, a very high proportion of data points were at 99.9 % RH or higher.

- The sensors with Condensation Guard enabled were in the saturation range far less often. Here, the proportion of data points at 99.9 % RH and above was significantly lower.

In addition, regular downward humidity steps are visible for those HTS401 units with Condensation Guard. They result from Condensation Guard activation at intervals of around 30 minutes, when the sensing element is briefly heated.

The key takeaway - an HTS401 with Condensation Guard enabled spends significantly less time in a condensation state at high humidity and follows humidity changes faster than a device without.

Outdoor test with dew and morning sun

A second test was carried out with HTS401 units outdoors over several days in October. At night, condensation formed on the sensor and filter cap. With sunrise, the ambient relative humidity gradually decreased.

Here too, two groups were compared:

- HTS401 with Condensation Guard disabled

- HTS401 with Condensation Guard enabled

The humidity chart makes it clear:

- The sensors without Condensation Guard remain at very high relative humidity for a long time after a condensation event, even though the air is already drying.

- The sensors with Condensation Guard broke away from these high values faster and reported the actual ambient humidity sooner.

After dew phases or rapid temperature changes, sensors with Condensation Guard enabled return to the true process value sooner instead of incorrectly remaining at 100 % RH for extended periods.

Easy calibration of the HTS401 using rapidX

Measurement stability in harsh conditions is critical. To maintain stability, calibration is necessary. The HTS401 offers rapidX technology which makes this easy by providing an intelligent sensor module that can be quickly changed in the field.

Traditional methods to calibrate humidity sensors

Depending on the process and quality requirements, there are a couple ways to calibrate a humidity sensor:

- Ship to a calibration laboratory. The sensor is removed, packed and sent to the lab. There, a calibration is performed against traceable standards, followed by a return shipment. During this time, the sensor is missing from the process, typically for up to three weeks.

- On-site calibration with a reference instrument. The sensor remains installed and is adjusted using a portable calibration system. Calibration can be carried out directly at the measurement point, which takes several hours.

Both approaches are proven in measurement technology, but each comes with its own cost either in downtime or out of the maintenance budget.

Measuring module replacement to eliminate downtime

This is exactly where the rapidX option of the HTS401 comes in. The HTS401 measuring module is intelligent and factory calibrated.

In the real world, this means:

- The rapidX measuring module can be exchanged in the field without tools and while the sensor is powered.

- A user simply removes the filter cap, swaps the module, replaces the filter, and recommissions This typically takes only a few minutes per sensor.

- Time-consuming on-site calibration is eliminated, as each rapidX module is calibrated at the factory.

- For every rapidX module, a digital inspection certificate in accordance with DIN EN 10204 3.1 is available via the E+E Certificate Service.

There is a clear difference between rapidX and the classic send-in-and-wait calibration. Instead of a measurement downtime of up to three weeks, calibration is accomplished in minutes. All while the sensor remains in operation.

When it comes to validated environments,such as the pharmaceutical industry and cleanrooms, the combination of a digital certificate and fast module replacement is a gamechanger. Measurement points remain documented and traceable without stopping critical systems.

For the use of this service, prior consent to the processing of your data and in particular to the setting of cookies is necessary. You can consent to the processing and setting of cookies here. Without your consent, your data will not be processed in connection with this service and no cookies will be set. You can revoke your consent at any time. For more information on cookies and the processing of your data in connection with this content and a way to revoke your consent, please see our privacy policy.

Added value from HVAC to cleanrooms

The HTS401 offers great measurement accuracy and flexible integration with minimal maintenance over the life of the sensor. It covers a humidity range from 0 to 100 % RH and achieves an accuracy of up to ±0.95 % RH as well as ±0.1 °C within the specified temperature range. The operating range spans from −40 to +80 °C.

Typical applications include:

- High-end HVAC in data centres, swimming pools or demanding building services

- Agricultural applications such as greenhouses, livestock barns, storage and maturation rooms

- Cleanroom monitoring in the pharmaceutical industry

- Process climate control in the food and beverage industry, for example for meat or cheese maturation

In many of these applications, high humidity and condensation occur regularly but cannot impede the sensor performance. At the same time, seamless documentation of measurement points is required. That is why the combination of Condensation Guard and rapidX is far more than a technical detail, it is a key building block for stable, cost-effective processes.

Conclusion

Condensation Guard and rapidX address two very practical questions when measuring humidity and temperature with the HTS401:

- How do I obtain reliable measurement results despite condensation?

- How do I keep my measurement point calibrated without interrupting the process?

The climate chamber and outdoor tests show that Condensation Guard, when enabled, significantly reduces the time spent in a condensation state and captures humidity changes close to 100 % RH more quickly.

With rapidX, calibration improves from a potentially weeks-long interruption to a quick swap with a digitally documented result. For operators, this means less effort, less risk, and considerably greater reliability.

If you would like to learn more about condensation-resistant humidity measurement with the HTS401 and rapidX, our E+E sensor specialists are happy to support you.

- Go to previous Blog Post: Robustness in Focus: How the AVS701 Proves Itself in Corrosive Environments Robustness in Focus: How the AVS701 Proves Itself in Corrosive Environments previous

- Environmental Monitoring in Pharma: How to Choose the Right Sensor Technology for Pharma Machinery next Go to next Blog Post: Environmental Monitoring in Pharma: How to Choose the Right Sensor Technology for Pharma Machinery