Industrial processes place stringent demands on instrumentation. Extreme ambient conditions, aggressive media, chemically intensive cleaning and the need for accurate, fail-safe data are common. Conventional sensors soon reach their limits because of condensation, corrosion, temperature extremes or labour-intensive maintenance. This is where the HTS401 excels.

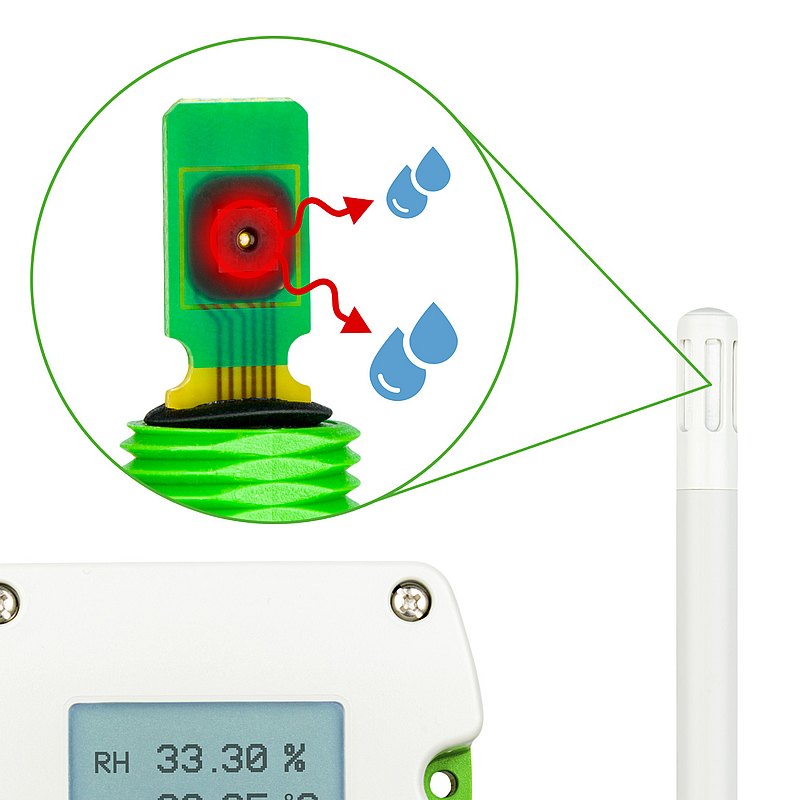

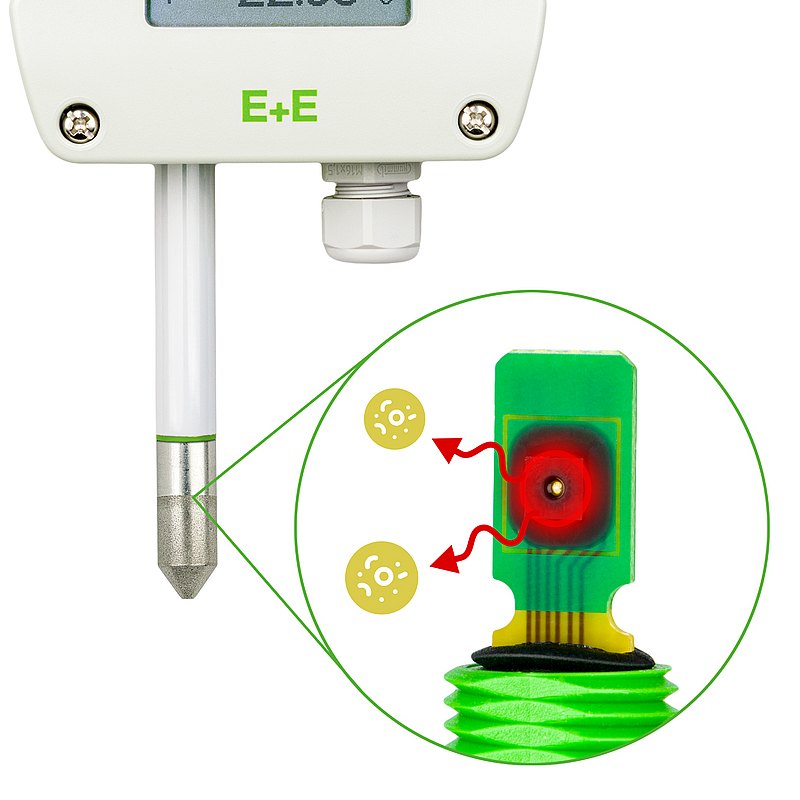

With a robust and intelligent protection concept that combines the E+E sensor coating with connection encapsulation, the HTS401 remains ready for service even under severe stress. The Automatic Recovery function (ARC) protects the sensing elements against adverse chemical influences. In the event of condensation risk, the Condensation Guard (CG) intervenes before measurement performance is affected.

Typical Applications

- High-end HVAC: data centers, swimming halls, outdoor applications

- Agriculture: greenhouses, stables, storage and ripening

- Pharmaceutical Industry: cleanroom monitoring

- Food and beverage: meat & cheese maturation

- Protective Sensor Coating

- rapidX Technology

- Automatic ReCovery (ARC)

- Condensation Guard (CG)

- IP65 / NEMA 4X protection rating

- All RH related physical quantities

- Modbus RTU

- Measuring range Humdity

- 0...100% RH

- Accuracy Humdity

- -15...40 °C <90% RH ±(0.95+0.0013*mv)% RH

- Measuring range Temperature (wall mount)

- -40...60 °C (-40...140°F)

- Measuring range Temperature (duct mount)

- -40...80 °C (-40...176°F)

- Accuracy Temperature

- ±0.1 °C (0.18°F)

- Accuracy Humidity

- ±0.95 % RH

- Analogue outputs

- 0-5V, 0-10V, 4-20mA, 0-20mA (3-wire)

Advantages of HTS401 with E+E Sensors

The HTS401 is engineered for continuous use in challenging environments. ARC, the heated sensing unit (Condensation Guard) and a specially developed protective coating work together to shield the sensor from permanent high humidity, aggressive media and residues from cleaning processes. Fully potted electronics and a sealed module connection complement the concept. The result is fewer corrosion-related failures, reduced measurement drift, longer sensor lifetime and significantly less maintenance. This is particularly valuable in applications with routine automated cleaning or sterilisation and in consistently humid conditions.

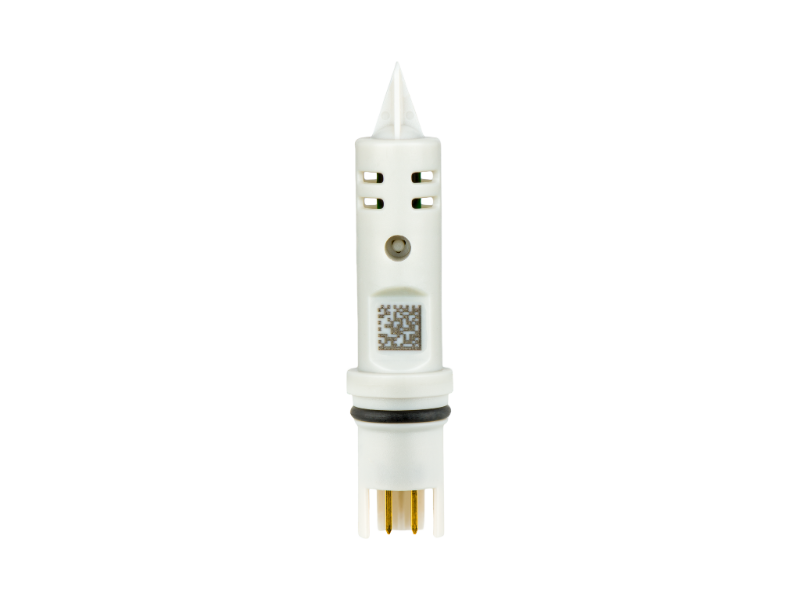

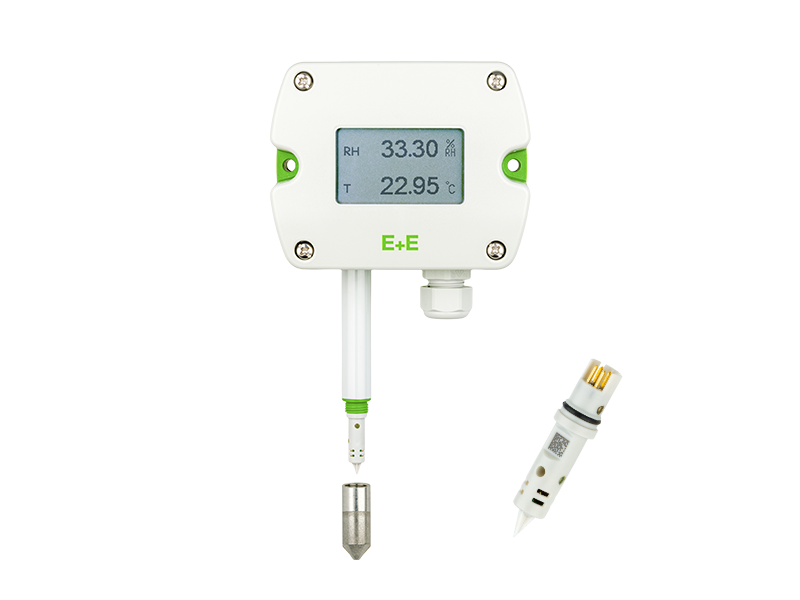

The HTS401 simplifies the maintenance and calibration of humidity and temperature sensors thanks to its integrated rapidX technology. The sensor module can be replaced in the field without tools in just 10 minutes – including filter replacement and access preparation. The rapidX exchange requires no special tools, no trained personnel, and no process interruption. On-site calibration becomes obsolete, as each rapidX sensor is factory pre-calibrated and delivered with a digital inspection certificate according to DIN EN 10204-3.1. The certificate can be accessed directly via the E+E certificate service.

For comparison: A traditional external calibration by sending in the sensor requires full disassembly and can result in a process interruption of up to 3 weeks. As an alternative, E+E Elektronik offers the Omniport 40 – a flexible handheld calibration system for on-site adjustment, particularly well-suited for customers with their own service infrastructure. The calibration process is fast and precise, taking around 70 minutes in the field.

The HTS401 features an integrated Condensation Guard. This active heating function at the sensing element lowers the risk of dew formation during operation. When ambient conditions indicate a condensation risk, the sensor temperature is raised slightly to counteract moisture build-up on the surface. The output signal remains stable during sudden temperature drops and in high-moisture applications such as cold stores, agricultural ventilation systems or outdoor installations. This function helps avoid measurement errors and failures caused by condensation without materially affecting measurement dynamics.

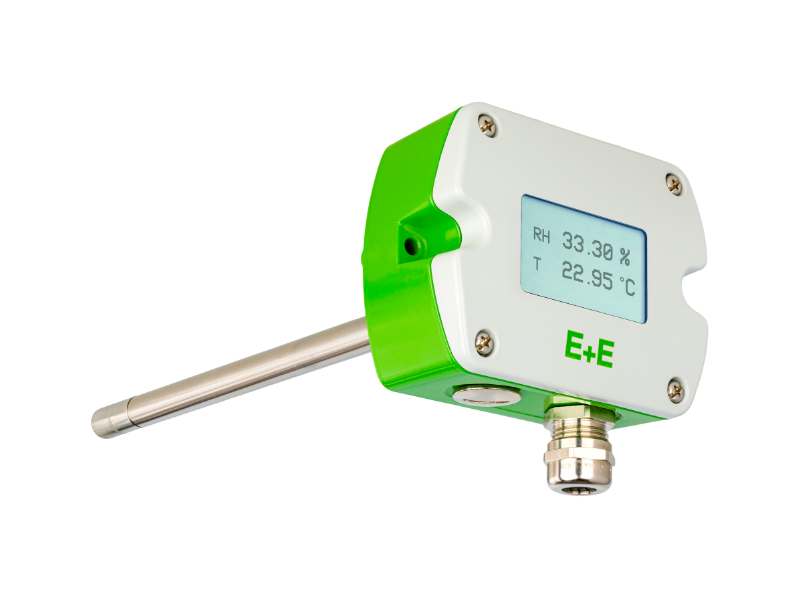

With accuracy up to ±0.95 % RH and ±0.1 °C (±0.18 °F), the HTS401 delivers reliable values even in sensitive processes. More precise control improves energy efficiency. Derived humidity parameters such as dew point, mixing ratio and enthalpy are calculated internally, which supports use in HVAC, cleanroom and agricultural processes. The −40 °C to +80 °C (−40 °F to +176 °F) operating range ensures reliable performance in heated and unheated environments, for example outdoors or in storage areas with variable climatic conditions.

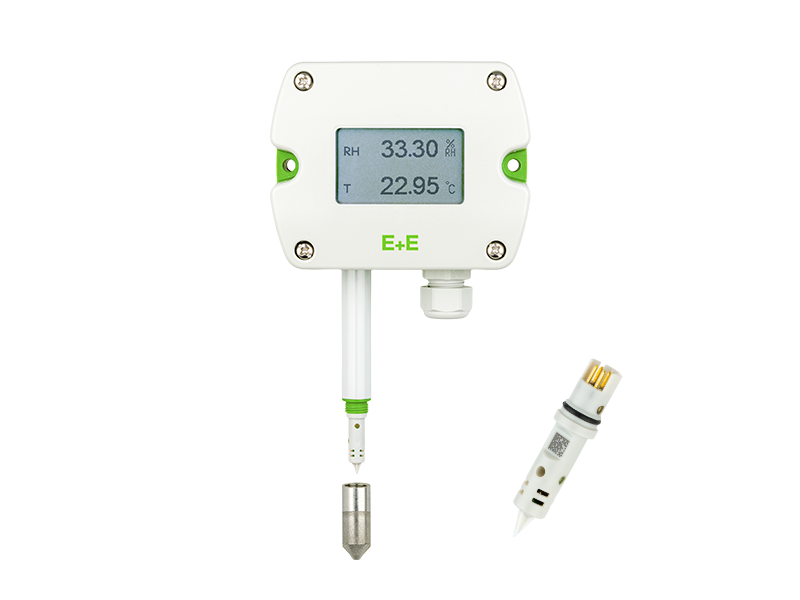

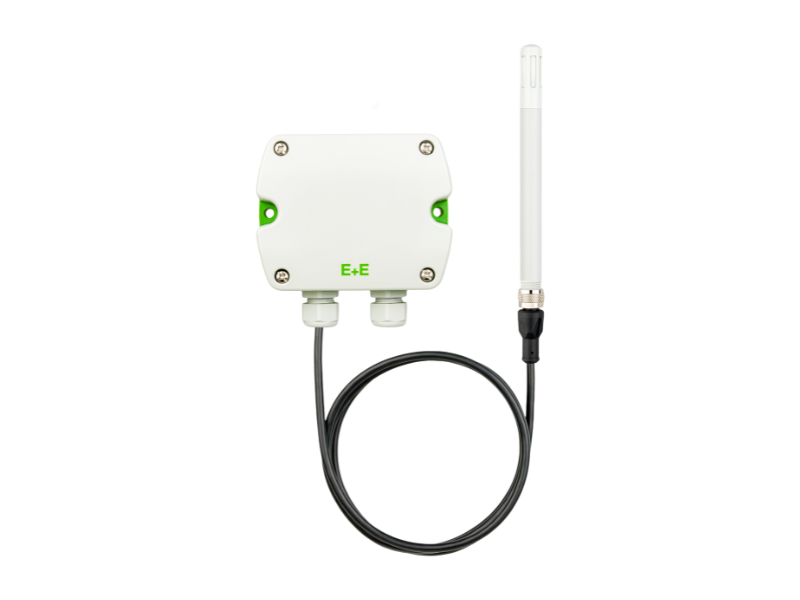

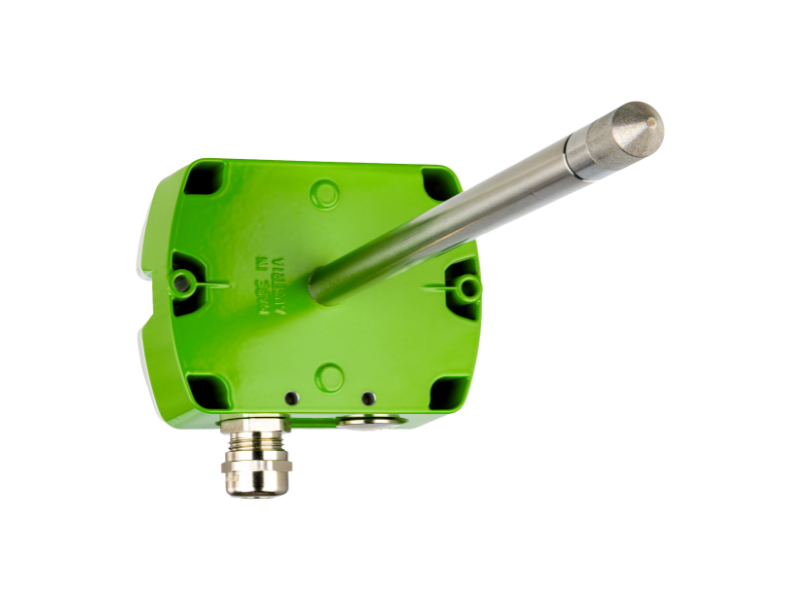

The HTS401 supports digital and analogue interfaces (RS-485 / Modbus RTU, 0–10 V, 4–20 mA) and can be fully configured using the E+E PCS10 software. Integration into existing systems is straightforward. Installation is fast, effort is low and parameters can be adjusted at a later stage. Wall-mount and duct versions are available, as well as remote-probe variants. An optional display allows multiple measured variables to be visualised simultaneously.

FAQ

Transmitter with "two-wire" technology receive the power from the process, and the signal is carried on return wire (closed current loop). With "three-wires" technology the power supply is separate from current output: 2 wires are the power supply and the third carries the signal.

Downloads HTS401

You want to know more about our products?

Tell us about your application – we’ll recommend a suitable sensor or calibration solution tailored to your needs.