Measuring Performance

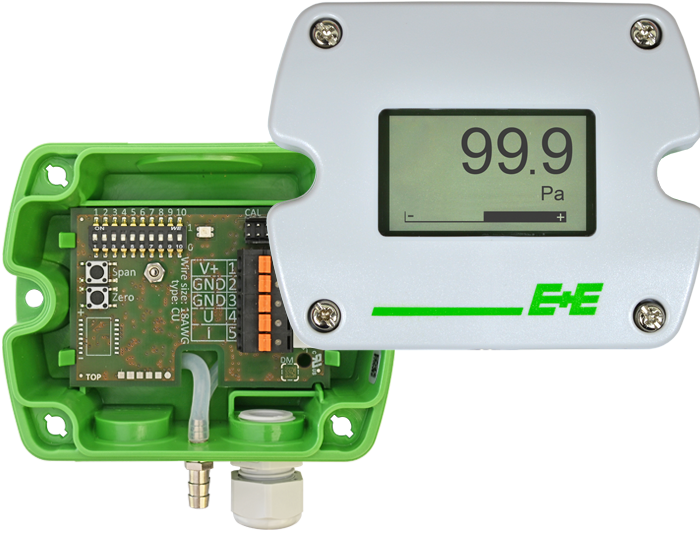

The EE610 offers ±0.5 Pa accuracy across the entire measuring range. The device has a maximum measuring range of ±100 Pa. With the analogue version, a measuring range of 25 %, 50 %, 75 % or 100 % of the maximum measuring range can be selected unidirectionally or bidirectionally. These settings can be made either via the PCS10 or via DIP switches. The piezoresistive, non-flow-through pressure sensing element stands for outstanding long-term stability.

Analogue and Digital Outputs

The measured data is available on the analogue voltage and current output or on the RS485 interface with Modbus RTU protocol.

Functional and Robust

The IP65 / NEMA 4X enclosure minimises installation costs. External mounting holes allow installation with closed cover, protecting the electronics against construction site damage and pollution.

Configurable and Adjustable

The setup can be easily performed with DIP switches on the electronics board (EE610 with analogue output) or with an optional stick and the free PCS10 Product Configuration Software. The setup includes measuring range, output signal, response time, displayed units and backlight. The auto-zero interval and the measuring range can also be set with the PCS10. A zero point and span adjustment can be easily performed using the push buttons on the electronics board.

- Configurable and adjustable

- Multi-range (analogue output)

- High accuracy (±0.5 Pa)

- Knockout for ½" conduit fitting (US)

- Service interface for configuration

- Graphic display with backlight

- Fully configurable

- Auto-zero interval (optional)

- Installation-friendly enclosure

- External mounting holes

- Measuring range

- 0...25 / 50 / 75 / 100 Pa

- Accuracy - *Full Scale

- ±0.5 Pa = 0.5 % FS*

- Working range - temperature

- -20...+60°C (-4...140°F)

- Feature

- Auto-zero function

- Overload limit

- ± 7000 Pa

- Analog outputs

- o-5V / 0-10 V0-20mA / 4-20mA

- Digital interface

- Modbus RTU

- Power Supply

- 15 - 35 V DC or 24 V AC ±20 %

FAQ

No, it is not recommended. It can have a negative effect on the measurement result and measurement accuracy, especially at a low pressure.

Transmitter with "two-wire" technology receive the power from the process, and the signal is carried on return wire (closed current loop). With "three-wires" technology the power supply is separate from current output: 2 wires are the power supply and the third carries the signal.

Downloads EE610

You want to know more about our products?

Tell us about your application – we’ll recommend a suitable sensor or calibration solution tailored to your needs.