Your Savings Potential in Wood Drying Systems

Accurate moisture measurement is the key to efficient and economical wood drying. It enables targeted control of the drying process, allowing for significant energy savings. At the same time, product quality is ensured through uniform drying. Cracking, warping, and other typical wood drying defects can be effectively avoided. This not only preserves the material value but also significantly reduces energy consumption. The result is greater sustainability and a long-term reduction in operating costs.

Modern sensor solutions provide continuous real-time monitoring of drying conditions, forming the basis for fully automated process control. This enhances both reproducibility and process reliability, particularly in high-volume production environments. In times of rising energy costs and increasing demands for resource efficiency, highly accurate moisture measurement represents a decisive competitive advantage—ensuring consistent product quality and enabling sustainable production.

How to Save Energy in Wood Drying

The costs of kiln-dried sawn timber strongly depend, among other things, on the final moisture content to be achieved. In this context, the issue of over-drying plays an important role. Corresponding studies have shown that the final moisture content not only determines energy consumption, but also has a significant influence on value losses due to warping and shrinkages.

Detailed investigations have shown that the degree of over-drying can be reduced by highly accurate moisture measurements during the entire drying process, thus additional capacities can be gained.

The following examples, based on a medium-sized sawmill, demonstrate the benefits that can be achieved by improving drying effectiveness through just a 1% reduction in overdrying. This seemingly small difference has a direct impact on both energy consumption and material quality, making it a critical parameter for optimising the drying process.

All calculations are based on a target wood moisture content of 15%, an actual dryness level of 14% wood moisture content (WMC), resulting in an overdrying of 1%.

Reduction of quality losses

| Quality loss/overdrying percentage | 1,5 % |

| Total quality loss [%] | 1,5 % |

| Lumber volume/year (m³) | 300.000 |

| Total quality loss [m³] | 4.500 |

| Loss [€/m³] | 40 |

| Additional profit/year [€] | 180.000 |

Increasing the drying capacity

| Sawn timber volume / year [m³] at 100 cycles | 300.000 |

| Capacity of the drying chamber [m³] | 250 |

| Drying time [h] at 100 cycles (~8,000 h operation) | 80 (spruce 50 mm at 18%) |

| Reduction / difference in drying time [h] | 3 |

| Cycles per year | 104 vs. 100 cycles |

| Annual additional drying capacity [m³] / chamber | 1.000 |

| Contribution margin for dried construction timber [€/m³] | 75 |

| Yearly income for additional dried timber [€] | 900,000 with 12 chambers |

Energy saving potential

| Drying kiln capacity (m³) | 250 |

| Total amount of drying kilns middle sized sawmill | 12 |

| Yearly capacity [m³] | 300.000 |

| Energy consumption thermal drying [kWh/m³] | 250 |

| Energy saving/over-drying percentage (kWh/m³) | 6 |

| Yearly total thermal energy consumption [MWh] | 75.000 |

| Energy savings/kiln and load (kWh) | 1.500 |

| Efficiency coefficient | 80% |

| Savings incl. efficiency (kWh) per load | 1.875 |

| Yearly savings MWh/kiln calculating with 100 loads | 187,5 |

| Energy price for 1 MWh natural gas [€] | 220 |

| Yearly Energy reduction less over-drying [€] per drying kiln | 41.250 |

| Yearly Energy reduction less over-drying [€] total | 495.000 |

Conclusion

Adding the three example calculations above, a medium-sized sawmill could achieve total savings of approximately €675,000 with just 1% less over-drying, in addition to potential extra revenue of around €900,000 due to increased drying capacity. These figures clearly demonstrate the importance of highly accurate and long-term stable moisture measurement for optimally controlling final moisture content.

Free Guide:

Improve efficiency inside your lumber kiln.

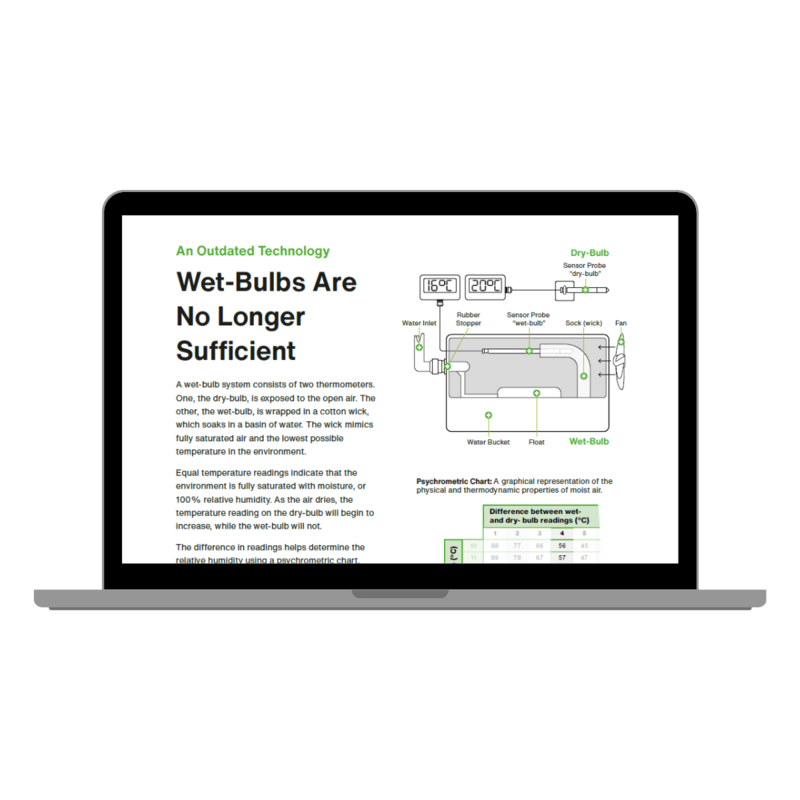

This free guide shows how switching to a digital humidity measurement system can enhance drying control, prevent over-drying, reduce human error, and significantly lower maintenance time and costs.

Get your free guide now

Let Us Help You Find the Right Sensor

Discover how E+E Elektronik sensor solutions can help you reduce energy consumption, prevent quality losses, and maximise process efficiency. Our experts are here to support you with tailored advice for your specific application.