Robustness in Focus: How the AVS701 Proves Itself in Corrosive Environments

In many industrial applications, air or gas velocity is just one of many measured variables. However, if the sensor fails, the entire system often comes to a standstill. Aggressive media, cleaning agents or a salty atmosphere attack materials and can significantly shorten the service life of the sensing technology.

This is exactly where the AVS701 air and gas velocity sensor from E+E Elektronik comes into play. Its ceramic sensing element with special coating, combined with a robust stainless-steel sensor head, is designed for use in harsh environments and has been thoroughly tested for this purpose.

Why robustness is crucial for air velocity sensors

In many processes, flow sensors are installed directly in the medium. The ambient conditions are often challenging. Humid or saturated air, cleaning and disinfecting agents such as H₂O₂, chemically aggressive gases such as ammonia, or a salty or dusty atmosphere can all take their toll on the sensor. Corrosion on the sensing element, solder joints or housing leads to drift, failure, or in the worst case to incorrect readings that go unnoticed. The consequences are:

- Quality issues in the process

- Unplanned downtime

- Increased effort and cost for maintenance and replacement

A flow sensor for demanding industrial environments must therefore not only measure precisely but also offer long-term stability and corrosion resistance. The AVS701 has been developed exactly with this in mind.

Engineered for tough applications

The robustness of the AVS701 starts with the mechanics and extends all the way to the sensing element:

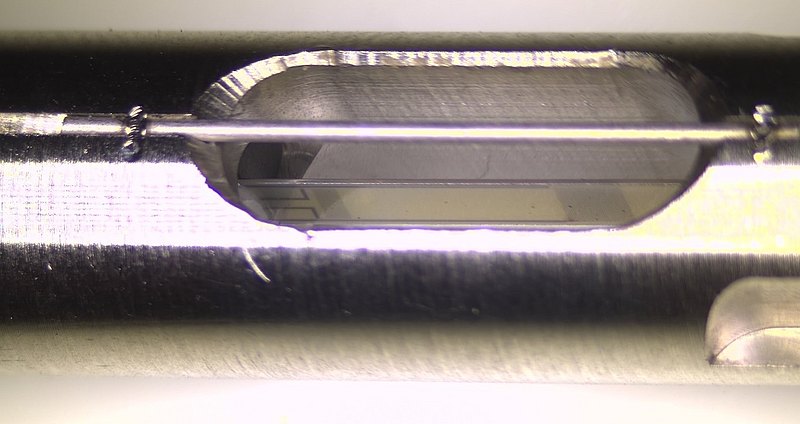

- Ceramic thin-film sensing element with protective coating

- Stainless-steel sensor head and probe

- High tightness and wide operating range

- Special coating for protection against corrosive media

The long-term tests in the E+E test laboratory demonstrate how effective these design measures are.

Corrosion resistance in salt spray

In practice, salty atmospheres occur, for example, in exhaust air systems, in the food industry or in installations near the coast. To assess the resistance of the AVS701 sensing element under such conditions, a salt spray test was carried out in accordance with DIN EN ISO 9227.

Test set-up at a glance:

- Standard-compliant salt spray with 50 grams of sodium chloride per litre of water

- Total test duration of 168 hours

- Sensor heads positioned completely within the test area

- Five AVS701 sensing elements each in metal housings with and without bluff body

- Three specimens of each variant energised during the test, two stored without power

- Resistance values of the heater and temperature sensor measured before and after the test

Result of the salt spray test

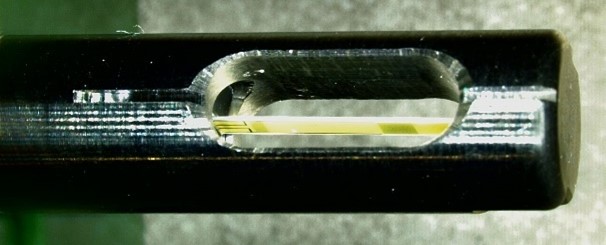

After 48 hours, visual inspection revealed no visible changes. After 168 hours and subsequent cleaning, the sensing elements were examined under the microscope. No signs of corrosion were found on the actual sensing element. Light deposits on the housing and sensor could be removed and were traced back to minerals from the water used.

The electrical resistances of the heater and temperature sensor remained within the expected range; the changes were minimal.

| Before Test | After Test | ||||

|---|---|---|---|---|---|

| AVS701 sensing element without bluff body | DUT number | Heater element in Ohms | Temperature sensor in Ohms | Heater element in Ohms | Temperature sensor in Ohms |

| 1 | 313,1 | 425,9 | 314,3 | 428,2 | |

| 2 | 310,4 | 420.5 | 311,3 | 421,9 | |

| 3 | 309,1 | 423,1 | 310,0 | 426,1 | |

| 4 | 311,3 | 423,9 | 312,6 | 425,9 | |

| 5 | 311,4 | 419,3 | 312,3 | 421,9 |

| AVS701 sensing element with bluff body | DUT number | Heater element in Ohms | Temperature sensor in Ohms | Heater element in Ohms | Temperature sensor in Ohms |

|---|---|---|---|---|---|

| 1 | 319,3 | 429,4 | 320,6 | 434,5 | |

| 2 | 317,6 | 435,5 | 319.5 | 435,1 | |

| 3 | 323,1 | 439,7 | 325,1 | 443,4 | |

| 4 | 321,2 | 439,8 | 322,4 | 443,7 | |

| 5 | 321,9 | 444,4 | 322,6 | 447,3 |

Table: Measured values of the test specimens

This means: the AVS701 sensor head with ceramic element and stainless-steel housing withstands salty, corrosive atmospheres over a long period without impairing the measuring function or the sensing element.

Long-term ammonia test: up to 20 times longer service life

Ammonia presents a particular challenge for many materials. In practice, it occurs, for example, in fertiliser production, exhaust gas treatment, in air from animal housing, or in specific chemical processes. To assess the robustness of the AVS701 under such conditions, a long-term test with ammonia vapours was carried out in the E+E test laboratory.

Comparison of AVS701 with a conventional sensing element:

- Five conventional sensing elements and five AVS701 sensing elements

- Atmospheric storage and operation above an aqueous ammonia solution with 25% concentration

- Test duration 1 000 hours

- Three sensors of each type energised during the test, two stored without power

- Resistances of the heater and temperature sensor measured before and after the test

Electrical and optical results

All five conventional sensing elements showed significant damage after exposure. In some cases there were open circuits, in others a strong drift in resistance values. Failures occurred between approximately 300 and 600 hours. All five AVS701 sensing elements remained fully functional electrically. No signs of corrosion were visible under microscopic inspection.

Mean time to failure (MTTF)

From the observed failures, a mean time to failure (MTTF) was calculated:

- MTTF of conventional sensing elements: approx. 440 hours

- MTTF of AVS701 sensing elements: approx. 9 400 hours

This means that under this ammonia exposure the AVS701 is around 20 times more durable than the conventional sensing elements used for comparison. For operators of systems with chemically aggressive atmospheres, this translates into:

- Significantly longer service life of the sensing equipment

- Less unplanned downtime due to corrosion

- Reduced life cycle costs with consistently stable measurements

Conclusion: Robust sensing pays off

Corrosion is one of the most frequent causes of premature sensor failure in industrial flow measurements. In standardised salt spray tests and in internal long-term tests with ammonia vapours, the AVS701 demonstrates that its ceramic sensing element with protective coating and stainless-steel sensor head withstand these stresses reliably.

This means:

- High measurement stability even in corrosive atmospheres

- Longer maintenance intervals and plannable downtime

- Lower spare parts and service costs over the entire life cycle

Combined with its high measurement accuracy, wide velocity and temperature range, and simple installation, the AVS701 is an ideal flow sensor for applications where reliability and robustness are top priorities. If you would like to evaluate how the AVS701 can be used in your specific application, the E+E team will be pleased to support you with expert advice.