Advantages of Stables, Hatchers & Incubators with E+E Sensors

Common interfaces such as Modbus, analogue or digital outputs enable seamless system integration. Thanks to standardised protocols, system integrators, technicians or operators can continue using existing infrastructure and incorporate the acquired data into their control systems – without the need for additional configuration. This saves time during commissioning and makes the sensors ideal for retrofit projects in greenhouses, livestock facilities or storage units.

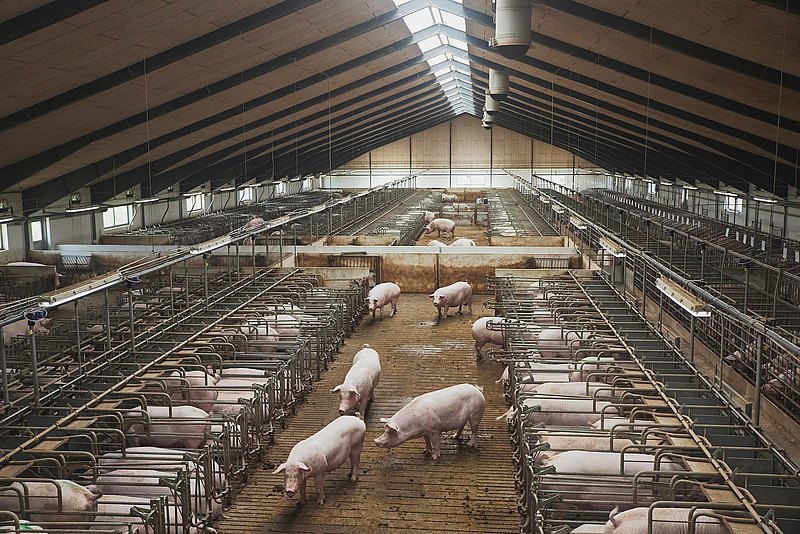

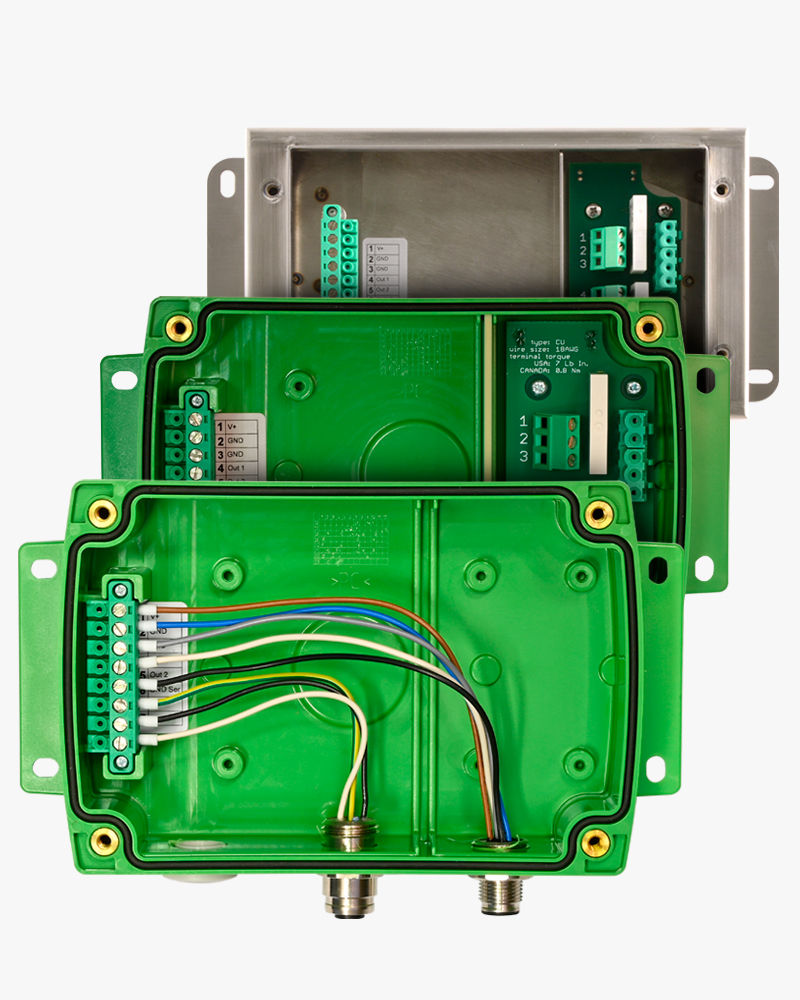

Especially during cleaning cycles with disinfectants, in dusty environments, and with heavy chemical exposure from animal waste, sensors must operate reliably. E+E sensors are designed to handle these challenges. Robust design features include:

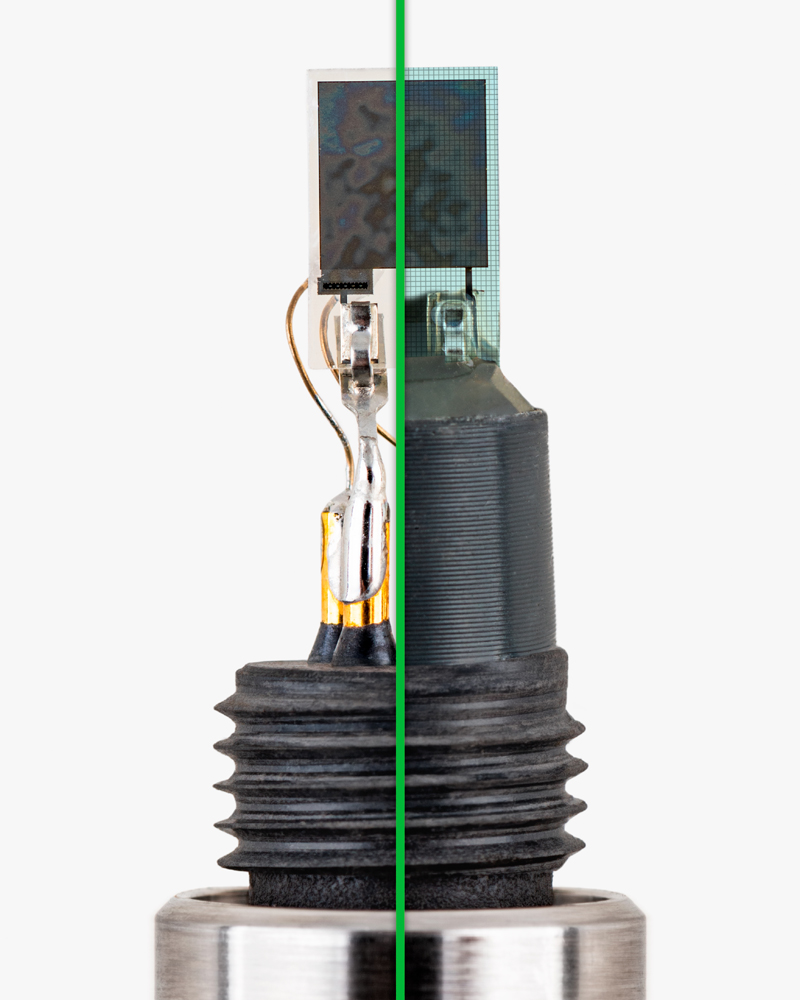

- Heated humidity sensors – The integrated sensor heating (High Humidity Guard) prevents condensation and ensures consistently accurate readings even under high humidity or condensation risk. This extends sensor lifespan and reduces maintenance effort.

- IP65/IP67-rated housings and interchangeable filters – These features prevent the ingress of dust and water, ensuring maximum operational reliability – even during high-pressure cleaning or H₂O₂ sterilisation.

- E+E sensor coating – A specially developed hygroscopic protective layer covers the active sensing element. It protects against dust, corrosion and moisture exposure, delivering long-term stable measurement performance.

- Innovative sensor encapsulation – A specially engineered protective capsule shields the electronics from fine dust, dirt particles and chemical contaminants. This ensures reliable operation even in heavily polluted environments.

These features help maintain measurement accuracy even in harsh conditions without removing the sensor from operation for frequent cleaning and calibration.

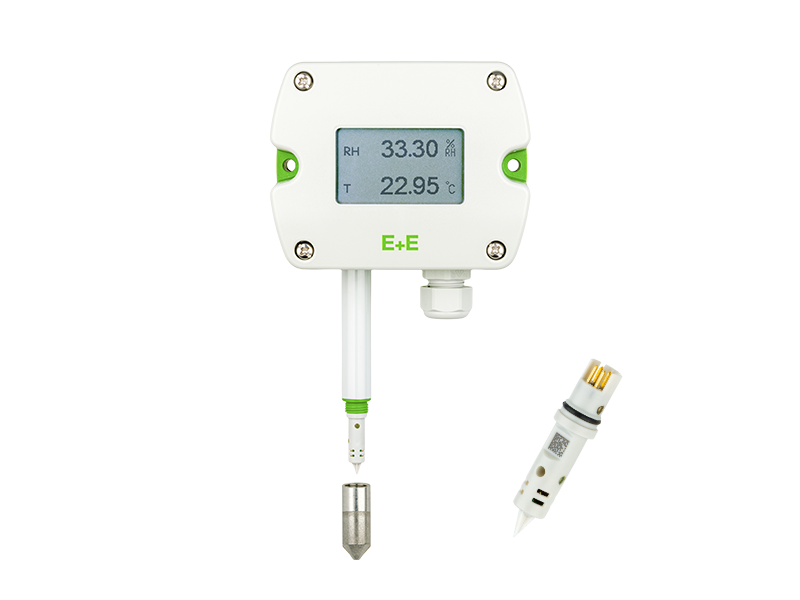

E+E Elektronik sensors deliver precise measurements for temperature (±0.2 °C), humidity (±2 % RH), CO₂ (±50 ppm), air velocity (>0.1 m/s) and differential pressure (±1 Pa). This enables precise control of all climate-relevant parameters - including incubating, rearing, and housing the animals. The benefits become clear when looking at the economic impact of heat stress and poor air quality:

- In dairy farming, performance declines measurably with rising temperatures or increased CO₂ levels– leading to up to 10% lower milk yield or delayed lactation. In dairy farming, milk output declines with rising temperatures or increased CO₂ levels, leading to 10% lower milk yield or delayed lactation.

- In pig farming, elevated barn temperatures result in reduced feed intake, increased piglet mortality, and fertility issues, causing estimated losses of $20 to $30 per animal.

- Calculations in poultry farming show that demand-based CO₂-controlled ventilation, instead of constant airflow, can save over $100,000 in heating costs during the winter. This equates to energy savings of around 30%.

Improvements can be adopted across nearly all stable and incubation environments in which precise sensor technology aids in animal welfare and reduces operating costs.

E+E sensors use probes and components can be quickly and easily replaced without removing the device from service. This eliminates unnecessary downtime and ensures long-term operational reliability. E+E’s modular design allows the operator to simply swap out sensing module without powering off the device.

Products for Stables, Hatchers & Incubators

For the use of this service, prior consent to the processing of your data and in particular to the setting of cookies is necessary. You can consent to the processing and setting of cookies here. Without your consent, your data will not be processed in connection with this service and no cookies will be set. You can revoke your consent at any time. For more information on cookies and the processing of your data in connection with this content and a way to revoke your consent, please see our privacy policy.

Trusted by our customers

Questions about Stables, Hatchers & Incubators?

Tell us about your application – we’ll recommend a suitable sensor or calibration solution tailored to your needs.