Advantages of E+E Sensors for Mushroom Cultivation

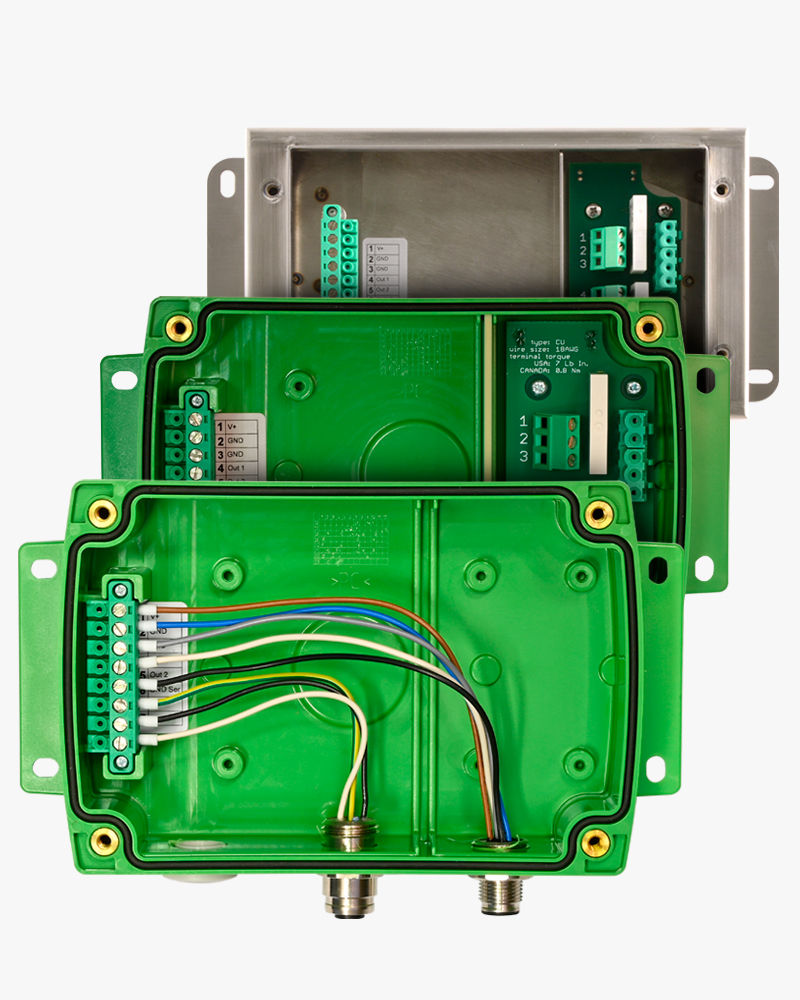

E+E sensors are designed so that probes and components can be quickly and easily replaced without removing the device from service. This eliminates unnecessary downtime and ensures long-term operational reliability. E+E’s modular design allows the operator to simply swap out the existing sensing module. No need to power off the device or calibrate on-site.

With a temperature accuracy of ±0.2 °C (±0.36 °F), long-term stable CO₂ deviation of ±50 ppm, and relative humidity measurement accuracy of ±2%, sensors from E+E Elektronik provide the foundation for precise climate control throughout all growth phases of mushrooms. A temperature deviation of 1 °C (1.8 °F) or humidity fluctuation of 5% can result in 10% of the mushroom grow being lost. This is equivalent to around $80,000 in annual revenue loss for a medium-sized mushroom cultivation facility (10,000 sq ft production area). Also consider that additional energy costs can add roughly $2,000 each year. Annual maintenance costs related to calibration, cleaning, or sensor replacement can also add up to $3,000. With precise sensor technology, these unnecessary costs can be avoided – delivering measurable improvements in quality, yield and efficiency.

Mushroom substrate, continuous high humidity, biofilm, dust, and H₂O₂can impair a sensors’ accuracy. Sensors operating in mushroom cultivation must maintain their reliability under these conditions. E+E Elektronik sensors are designed to meet these demanding requirements Robust design features include:

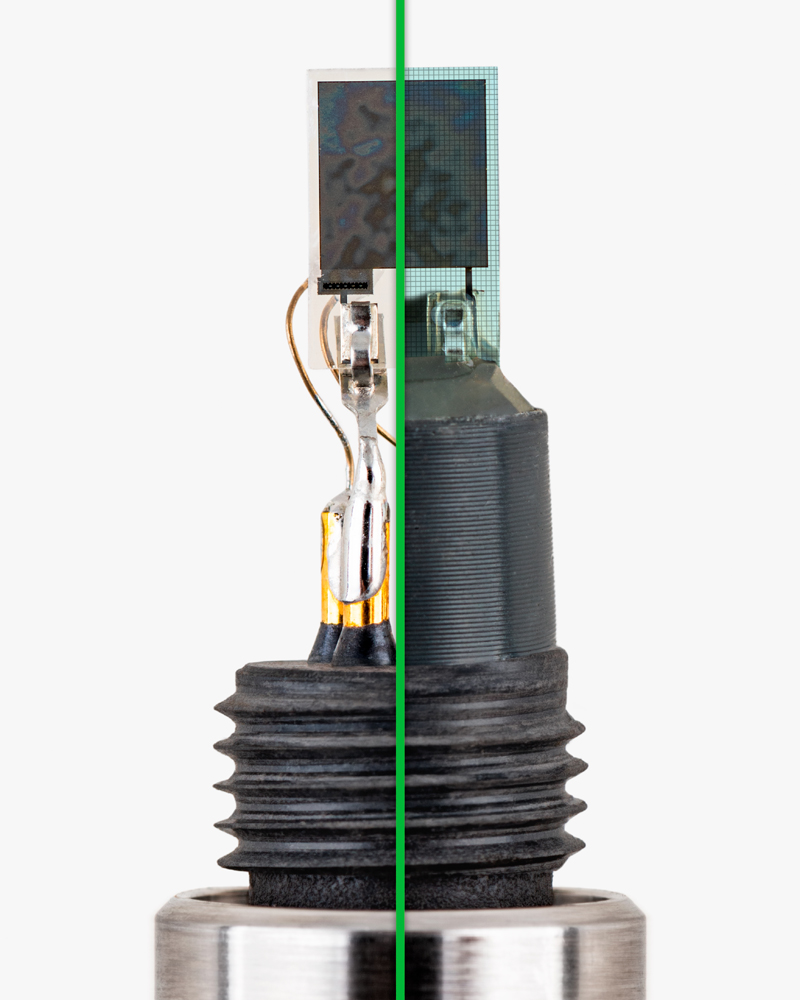

- Heated humidity sensors – The integrated sensor heating (High Humidity Guard) prevents condensation and ensures consistently accurate measurements, even at high humidity levels and with condensation risk. This extends sensor lifespan and reduces maintenance effort.

- IP65/IP67-rated enclosures and interchangeable filters – These features prevent the ingress of dust and water, ensuring maximum operational reliability – even under conditions such as high-pressure cleaning or H₂O₂ sterilisation.

- E+E sensor coating – A specially developed hygroscopic protective layer covers the active sensing element. It protects against dust, corrosion and moisture stress, delivering long-term stable measurement results.

- Innovative sensor encapsulation – A specially engineered protective capsule shields the electronics from fine dust, dirt particles and chemical exposure. This ensures reliable operation even in heavily contaminated environments.

Common interfaces such as Modbus, analogue or digital outputs enable seamless integration into existing climate control systems. Operators can configure the outputs to match the needed inputs and, thanks to this standardization, tie these directly into their existing infrastructure without reprogramming.

Products for Mushroom Cultivation

For the use of this service, prior consent to the processing of your data and in particular to the setting of cookies is necessary. You can consent to the processing and setting of cookies here. Without your consent, your data will not be processed in connection with this service and no cookies will be set. You can revoke your consent at any time. For more information on cookies and the processing of your data in connection with this content and a way to revoke your consent, please see our privacy policy.

Questions about Mushroom Cultivation?

Tell us about your application – we’ll recommend a suitable sensor or calibration solution tailored to your needs.