Advantages of E+E Sensors in Pharmaceutical Plants

With more than 40 years of experience and high vertical integration — from the sensing element to the calibrated device — E+E Elektronik delivers measurement reliability, compliance-ready monitoring, and long-term data stability for pharmaceutical plants worldwide. E+E sensors and software are built for the accuracy and traceability needs of cleanroom and controlled-environment applications, with accredited calibration available for humidity, dew point, CO₂, air velocity/flow, temperature, and pressure. Calibrations are performed in E+E’s EN ISO/IEC 17025-accredited laboratory (Akkreditierung Austria, ID 0608). The portfolio supports environmental monitoring in GMP Grade A/B (ISO Class 5) through ISO Class 8 areas — for example, the EE680 laminar-flow probe is specified for GMP Grade A/B and ISO 5 and above — while optional SmartGraph/HUMLOG software variants address FDA 21 CFR 11 requirements for electronic records

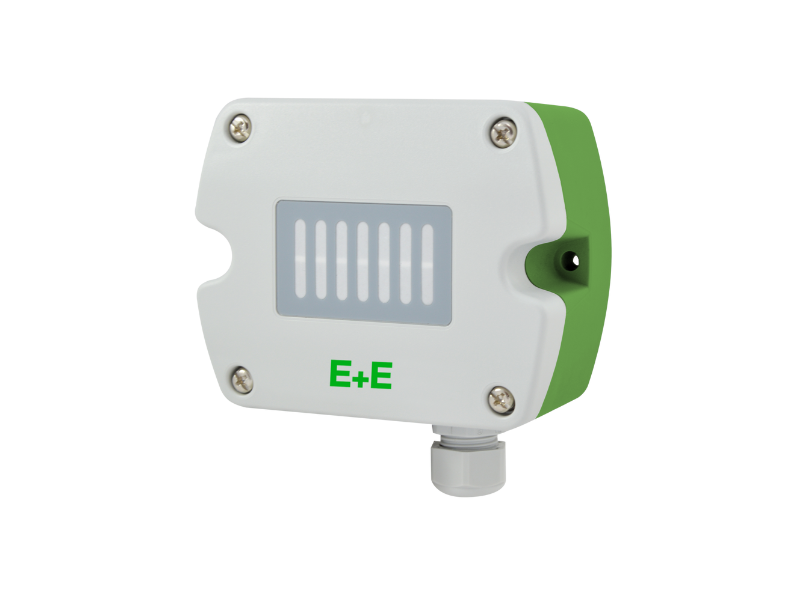

E+E cleanroom sensors — for example the GMP-compliant EE680 laminar-flow probe and the EE610 differential pressure sensor — are engineered for long-term stability in GMP-grade areas. Protective E+E sensor coatings, stainless-steel enclosures/connectors, and PTFE catalytic H₂O₂ filter caps help maintain accuracy even after repeated cleaning and H₂O₂ decontamination. This robustness helps minimise measurement drift during sterilisation and supports dependable performance in continuous operation.

From cleanroom airlocks and HVAC ducts to sterile production zones and storage areas, E+E offers a unified sensor portfolio for humidity, temperature, differential pressure, and air velocity/flow. With the modular Sigma 05 platform and dedicated cleanroom devices such as EE610 (low differential pressure) and EE680 (laminar-flow air velocity), the portfolio supports consistent measurement performance across all plant areas — from a single, trusted supplier.

Devices are typically supplied with a factory calibration certificate (EN 10204-3.1/2.2). On request, accredited ISO/IEC 17025 calibration certificates document traceability to SI and national standards; for selected measurands E+E acts as a BEV Designated Institute (NMI level). Periodic verification is easily performed with the Omniport 40 portable reference device, enabling fast on-site checks and — where applicable — direct probe adjustment. Digital calibration certificates provide immediate availability and simplify documentation. Together, these measures support ongoing GMP qualification and validation and help reduce the effort for requalification.

E+E transmitters integrate seamlessly into central monitoring systems for building management (BMS) and environmental monitoring (EMS). Analog outputs (4–20 mA, 0–10 V) and digital interfaces such as RS485 with Modbus RTU or BACnet MS/TP — and on selected models Ethernet PoE with Modbus TCP — enable reliable communication with common BMS/EMS platforms. The sensors’ stability and harmonised design help streamline qualification, validation, and long-term environmental data logging.

Products for Pharmaceutical Plants

Trusted by our customers

- Link to Ab&B Bio-Tech CO., LTD. JS

- Link to Airro Engineering Co.

- Link to Allyone Environmental Technologies India Pvt. Ltd.

- Link to Osworld Scientific Equipments Pvt. Ltd.

- Link to Brinda Pharma Technologies Pvt Ltd.

- Link to Exenity Systems Pvt Ltd

- Link to Glatt GmbH

- Link to NKT Pharma Pvt. Ltd.

- Link to Tofflon Science and Technology Group Co., Ltd

Questions about Pharmaceutical Plants?

Tell us about your application – we’ll recommend a suitable sensor or calibration solution tailored to your needs.