Why Choose E+E for Data Center Environmental Monitoring

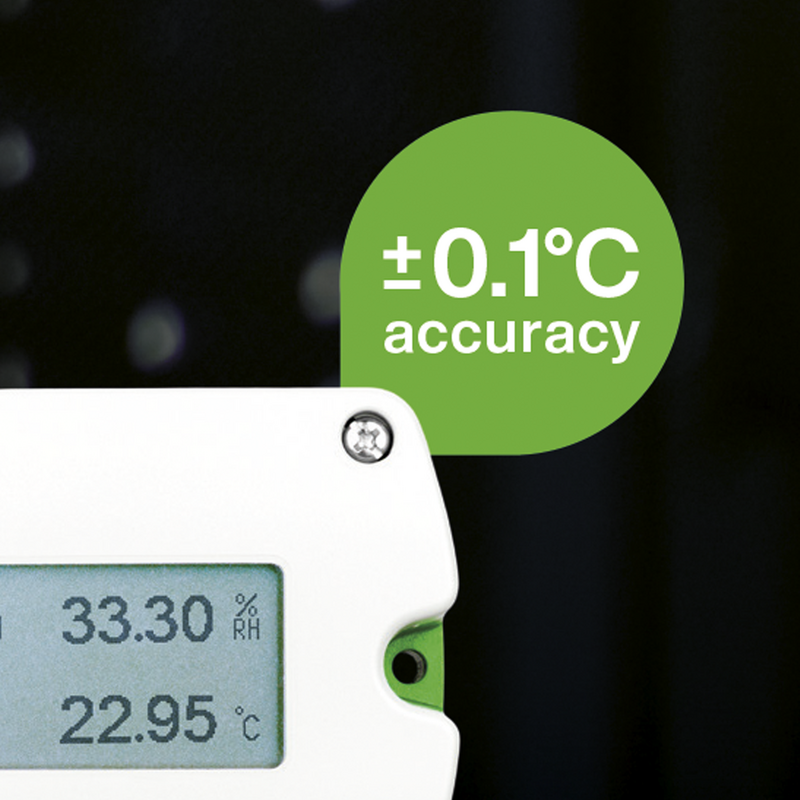

In a data centre, measurement accuracy is not a technical detail – it is a direct lever for efficiency. Anyone who wants to intentionally raise the server inlet temperature or control air volumes cleanly can only do so if temperature, air velocity, humidity and pressure are captured reliably and reproducibly. This results in more stable control, reduces unnecessary safety margins, lowers cooling energy demand and creates the foundation to implement efficiency measures safely without endangering uptime. E+E Elektronik, for example, provides highly accurate temperature sensors with an accuracy of ±0.1 °C.

Based on the rule of thumb that the cooling energy demand drops by around 9% per +1 °C higher server supply air temperature, increasing the temperature by just 0.4 °C and assuming an electricity price of €0.15/kWh saves around €200,000 per year (with 8,760 operating hours, 10 MW IT load and a PUE of 1.40). The compact design also enables a higher measurement-point density and thus better overall control quality across the system.

Data centre operators cannot afford downtime – neither for maintenance nor for calibration cycles. E+E Elektronik sensors score here with maintenance-friendly concepts that help standardise processes and keep availability high. A flexible design for a wide range of installation options simplifies integration into existing systems.

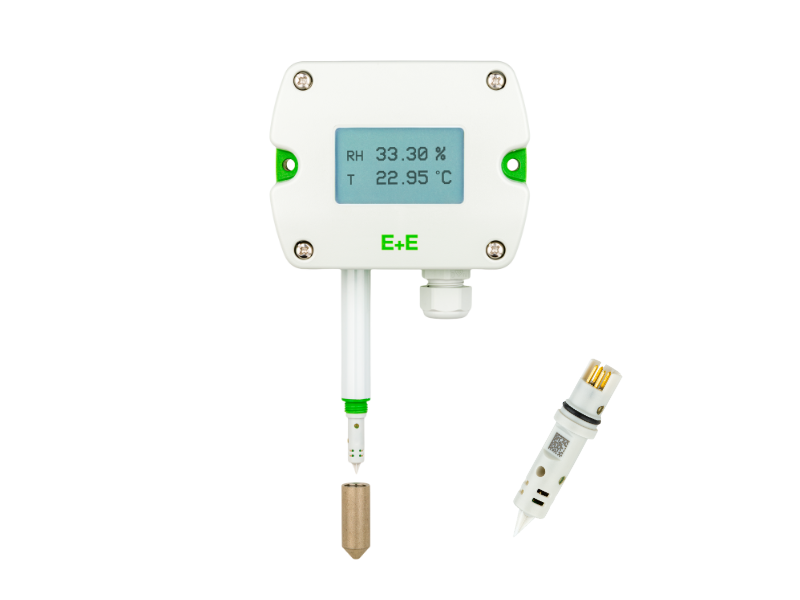

For example, the HTS401 humidity and temperature sensor features innovative rapidX technology: an intelligent, factory pre-calibrated measuring module that can be exchanged directly in the field in just 10 minutes. In addition, E+E Elektronik sensor solutions have a modular design, allowing probes and components to be replaced quickly and easily. Wall-mount and duct-mount options complete the portfolio

Efficiency, compliance and quality make traceable data indispensable – for audits, internal standards, SLA arguments or cross-site comparability. E+E Elektronik combines sensor technology with a strong calibration and documentation approach: measurement results are made verifiable. E+E sensors are calibrated in-house in a laboratory accredited to EN ISO/IEC 17025. Each device is delivered with complete, traceable documentation, providing the security and transparency required in standardised environments.

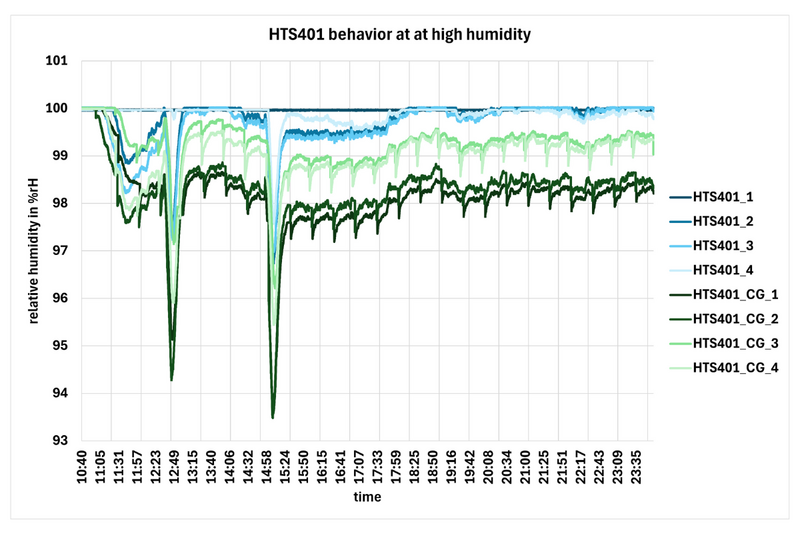

In the data centre, long-term performance is what counts. Drift, ageing, contamination or critical humidity conditions can gradually change readings and make control strategies silently inefficient or risky. E+E Elektronik’s in-house sensing element development clearly focuses on long-term product stability. Decades of know-how in selecting the right materials prevents typical drift and ensures reliable measurements over the entire service life.

In addition, innovative protection concepts against humidity or harsh ambient conditions such as sensor coating, encapsulated sensor connections, the Automatic Recovery function (ARC) or a Condensation Guard enable stable measurements without loss of quality. This reduces maintenance effort, lowers false alarms and ensures that highly accurate measurements remain a given long after commissioning

Data centres are developing towards higher density, more dynamic cooling strategies and greater automation. E+E supports this change with a broad, consistent portfolio and clear standards in interfaces (analogue and digital) and system integration. The result is a reliable data basis for efficient operation today and for further optimisation tomorrow.

For more than 40 years, E+E Elektronik has provided solid application know-how – from typical measurement points in the white space to HVAC and containment applications, through to integration into BMS/BAS structures. This creates solutions that are not used in isolation, but integrated into the overall system. For operators and OEMs, that means less coordination effort, faster commissioning and a measurably more stable monitoring concept.

Products for Data Center Environmental Monitoring

Why accurate environmental monitoring matters in data centres

That is exactly where sensor technology shifts from a “monitoring add-on” to a real lever. HVAC and climate control account for more than 30% of a data centre’s total energy consumption, making them one of the biggest consumers on site. Even the smallest changes to the server inlet temperature can have a noticeable impact on energy demand. An increase in inlet temperature of just 0.5 °C can save around 4–5% of energy consumption. To use this potential effectively, one thing is essential: stable, highly accurate measurements captured exactly where they are relevant for control and verification.

In practice, it is not only what you measure, but also where: in the white space (close to racks / the cold aisle), in the supply air, in pressure zones / containment, at filters or outdoors for free-cooling strategies. Easy installation, a space-saving design and seamless integration into existing systems are critical prerequisites. At the same time, requirements for documentation and compliance with standards are increasing (e.g. ASHRAE, DIN EN 50600 / ISO 22237).

Questions about Data Center Environmental Monitoring?

Tell us about your application – we’ll recommend a suitable sensor or calibration solution tailored to your needs.